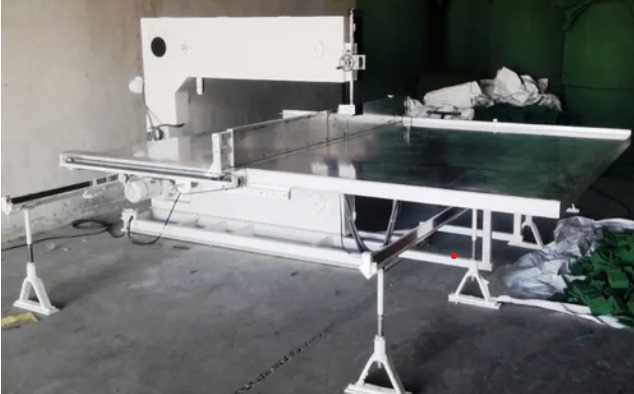

Abrasive Pad

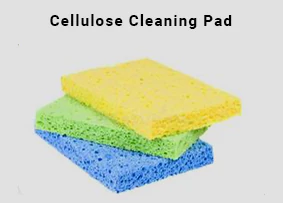

Bandknife Blades

We have the widest range of blades suitable for abrasive pad conversion available in various widths, thicknesses, and lengths to meet diverse cutting requirements. Engineered for smooth cutting, our blades reduce friction and heat buildup during operation, enhancing cutting performance and prolonging blade lifespan. This design feature contributes to overall cost savings. while ensuring efficient and accurate production processes with clean and consistent cuts.

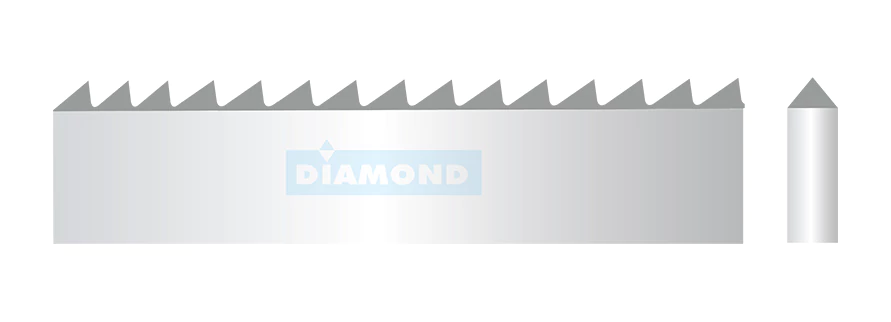

For the bare blocks with a high abrasive content we have the Angle / C Type with All Teeth Set.

The Angle tooth with a knife edge and a special angle tooth which gives double the output.

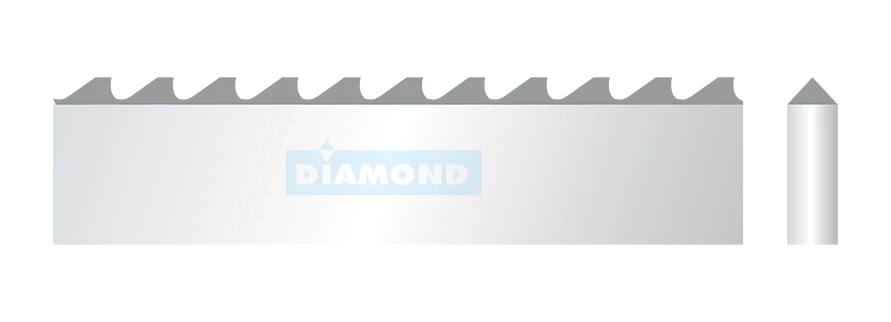

For the abrasive pads with a low abrasive content and/or with a foam backing we have a range of blades to give sharp and clean cuts.

Knife Edge / DBSE

The Double Bevel Single Edge blade stands as the most ubiquitous cutting edge, serving various cutting, slicing, and peeling tasks. It finds application across vertical, horizontal, carousel, peeling, slicing, and CNC machines.

Knife Edge / DBDE

Double Bevel Double Edge is used on vertical cutting machines to enhance productivity. Cutting takes place when the table is pushed forward and also while reversing the table. Requires 4 grinders.

Knife Edge Twisted / DBDE

The Double Bevel Double Edge Twisted blade is utilized on vertical cutting machines to elevate productivity and achieve tight tolerances. It enables cutting during both forward and reverse table movements, requiring only two grinders for operation.

V tooth Serrated DBSE / Diamond Pointed Tooth

Available in: 6, 8, 10, 14 & 18 TPI

The V toothed pointed is a popular profile. This profile is aggressive as compared to the knife edge blade. Generates some dust. Good for cutting hard foams and helps in avoiding the sharpening mechanism on the cutting machine. Used on vertical, horizontal, carousel, and CNC machines.

Angle Tooth DBSE / C type

Available in: 2, 4, 6, 8, 10 & 14 TPI

The Angle Toothed Double Bevel Single Edge is far more aggressive in its cutting action.

V tooth Serrated DBDE/ Diamond Pointed Tooth

Available in: 6, 8, 10, 14 & 18 TPI

The V toothed serrated Double Bevel Double Edge apart from faster cutting also helps in higher productivity as the cutting takes place when the table is pushed forward and also while reversing the table. Used on Vertical cutting machines.

Angle Tooth DBDE / C type

Available in: 2, 4, 6, 8, 10 & 14 TPI

The Angle Toothed Double Bevel Double Edge apart from faster cutting also helps in higher productivity as the cutting takes place when the table is pushed forward and also while reversing the table. Used on the vertical cutting machine.

Notch Tooth DBSE

The Notch Tooth DBSE is specifically engineered for foam cutting applications, offering exceptional precision and control. Its unique notch tooth design allows for clean and accurate cuts through various densities of foam materials, including polyurethane foam, memory foam, foam rubber and insulating material.

Notch Tooth DBDE

The Notch Tooth DBDE is specifically designed for precision cutting in foam applications. With its

unique notch tooth design, this blade ensures smooth and accurate cuts, minimizing material

waste and improving overall efficiency. Whether cutting foam for packaging. upholstery, or

insulation, the Notch Tooth DBDE Band Knife Blade provides exceptional performance and

reliability]

Flat Tooth DBSE

The Flat Top with an Flat Notch Double Bevel Single Edge is an Hybrid which combines the Knife Edge with a Flat Notch to give a higher productivity through its interrupted cutting. Used on vertical, horizontal, carousel and CNC machines.

Flat Tooth DBDE

The Flat Top with a Flat Notch Double Bevel Double Edge is an Hybrid which combines the Knife Edge with a Flat Notch to give a higher productivity through its interrupted cutting. The Double Edge enhances productivity as the cutting takes place when the table is pushed forward and also while reversing the table. Used on a vertical cutting machine.

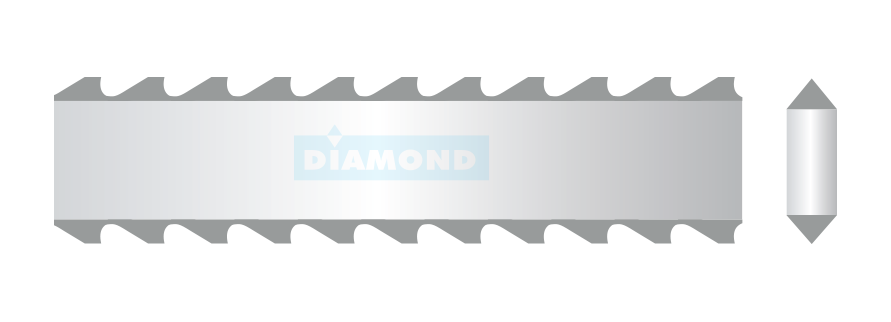

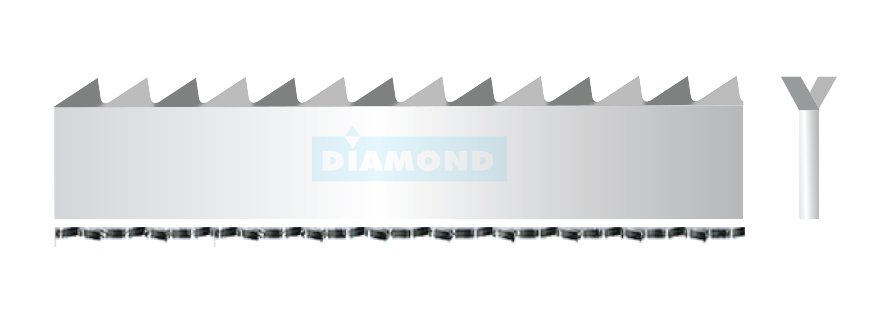

Angle Tooth All Tooth Set DE

Available in: 4, 6, 8, 10 & 14 TPI

The All Tooth Set Angle Toothed Single Edge is far more aggressive in its cutting action and offers a higher productivity as the cutting takes place when the table is pushed forward and also while reversing the table. The tooth set helps in cutting rigid foam, very high density rebonded foam and abrasive pads. Used on a vertical cutting machine.

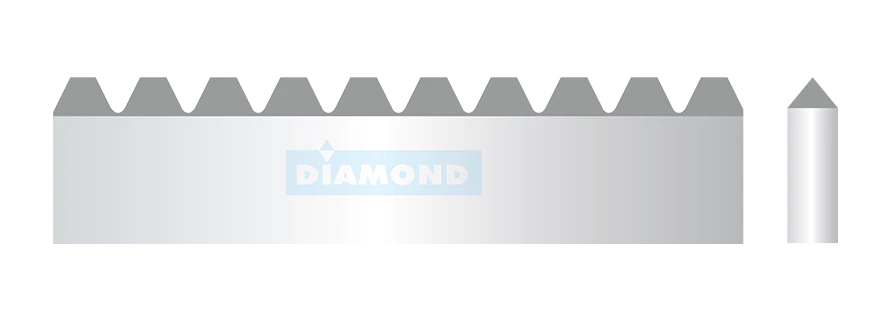

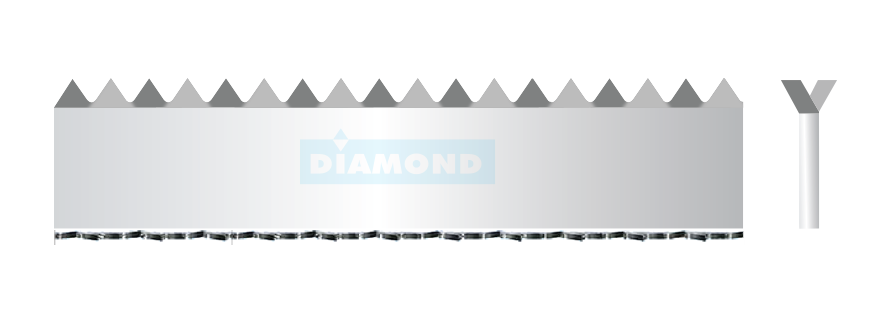

Pointed Tooth All Tooth Set DE

Available in: 4, 6, 8, 10 & 14 TPI

The All Tooth Set Pointed V Toothed Double Edge is far more aggressive in its cutting action and offers a higher productivity as the cutting takes place when the table is pushed forward and also while reversing the table. The tooth set helps in cutting rigid foam, very high density rebonded foam and abrasive pads. Used on a vertical cutting machine.

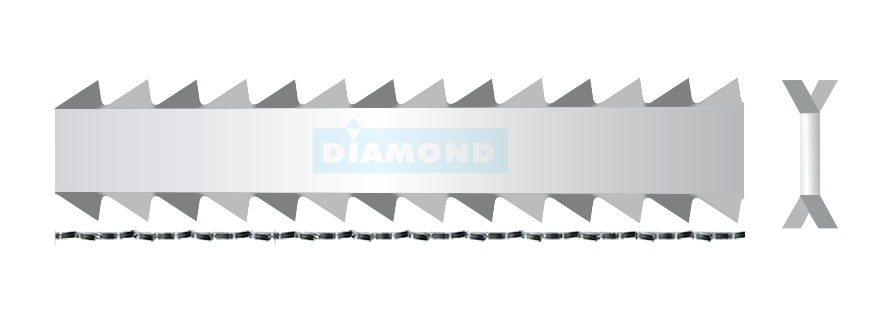

Angle Tooth All Tooth Set SE

Available in: 4, 6, 8, 10 & 14 TPI

The All Tooth Set Angle Toothed Single Edge is far more aggressive in its cutting action. The tooth set helps in cutting rigid foam, very high density rebonded foam and abrasive pads. Used on vertical, horizontal and carousel machines

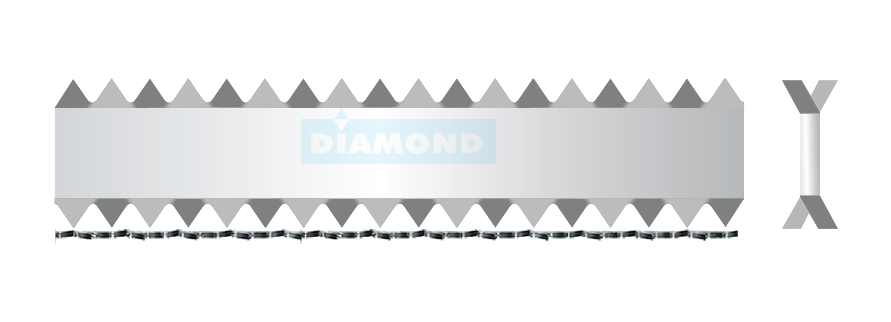

Pointed Tooth All Tooth Set SE

Available in: 4, 6, 8, 10 & 14 TPI

The Pointed V toothed All Tooth Set is an aggressive profile and is used in cutting rigid foam, very high density rebounded foam and abrasive pads. Used on vertical, horizontal and carousel machines.

Width in mm | Thickness in mm |

|---|---|

8 | 0.45 |

10 | 0.45 |

12 | 0.45 / 0.50

|

15 | 0.45 / 0.50 / 0.60 |

20 | 0.45 / 0.50 / 0.60 |

25 | 0.45 / 0.50 / 0.60 |

Width in Inches | Thickness in Inches |

|---|---|

0.314 | 0.017 |

0.393 | 0.017 |

0.472 | 0.017 / 0.019 |

0.590 | 0.017 / 0.019 / 0.023 |

0.787 | 0.017 / 0.019 / 0.023 |

0.984 | 0.017 / 0.019 / 0.023 |