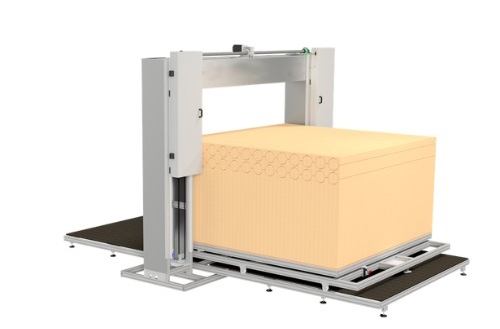

Foam Glass, Rebonded Foam, Rockwool

Abrasive Wires

Available Diameters in mm | 1.0 – 1.2 |

|---|

1.2 – 1.5

|

1.5 – 1.7

|

1.5 – 1.8 |

1.8 – 2.0 |

Available Diameters in Inches | 0.039 – 0.047 |

|---|

0.047 – 0.059

|

0.059 – 0.066

|

0.059 – 0.070 |

0.070 – 0.078 |

Types of Abrasive Cutting Wires

Abrasive Cutting Wire - Smooth Single Ring

This wire type is employed when minimal dust generation is desired. Its smooth final toroidal winding makes it ideal for cutting soft foams with minimal dust production.

Abrasive Cutting Wire - S Wrap Single Ring

Named for its distinctive S-shaped winding pattern, the S Wrap wire is a medium-grade option formed through Coaxial S winding in the penultimate cycle, followed by a final Toroidal winding, resulting in a mildly aggressive finish. Some dust may be inevitable when using the S Wrap wire.

Abrasive Cutting Wire - X Wrap Single Ring

The X Wrap wire demonstrates aggressive cutting performance, producing a considerable amount of dust and yielding a rough finish. Certain abrasive materials may necessitate the use of an X Wrap wire for cutting or shaping.

Double Ring Abrasive Cutting Wires

Abrasive Cutting Wire - Smooth Double Ring

Abrasive Cutting Wire - S Wrap Double Ring

Abrasive Cutting Wire - X Wrap Double Ring

Tungsten and Molybdenum Abrasive Cutting Wires

Tungsten and Molybdenum wires offer alternative solutions for materials that cannot be efficiently cut with the carbon steel wire commonly used in abrasive wires. To address this challenge, Tungsten or Molybdenum is employed for the final Toroidal winding, while carbon steel is used for the coaxial inner winding. Even for Tungsten and Molybdenum these wires are available in Smooth, S Wrap, and X Wrap configurations, both in Single or Double Ring Construction.

Tungsten-Coated Abrasive Cutting Wire

Molybdenum-Coated Abrasive Cutting Wire