Custom CNC Contour Cutting Blades: Precision Cutting for Your Business

Do you want to replace your dull CNC blades? Diamond Band Knife Co. crafts custom CNC blades for precision cutting. We cater to professionals looking for high-quality knives for their applications. Our blades elevate your cutting operations, ensuring precision, efficiency, and exceptional product quality. Ditch the generic blades and try our sharp CNC blades.

The Diamond Band Knife Co. Difference

At Diamond Band Knife Co., we’ve spent decades mastering the art of CNC blade design and manufacturing. We match each blade to your specifications to make your work easier.

Premium Materials

We believe in building blades that last. We source the finest materials for our manufacturing process, ensuring durability and longevity even in demanding environments. Our blades withstand wear and tear. You won’t have any problems with downtime and productivity.

We Answer Your Questions

Choosing the right blade can be tricky. That’s why our customer support team is always here to help. We’ll answer your questions, offer expert advice, and make sure you find the suitable blade for your application.

Choose From Our Custom CNC Blades

Reciprocating/Oscillating CNC Contour Cutting Blades

Ideal for precise cuts in foam used in furniture and mattresses. Choose V-Tooth Pointed blades with varying TPI (teeth per inch) for your material.

Continuous Band CNC Contour Cutting Bandknife Blades

Designed for continuous band cutting of foam, rubber, and plastics. Our Double Bevel Single Edge (DBSE) blades are versatile for many industries.

Endless Bandknife CNC Contour Cutting Blades

These blades are flexible for contour cutting, perfect for intricate designs. Choose Micro Convex blades for soft foams, Flat Tooth blades for general cutting, or Angle & Flat Notch blades for a combination of cutting styles.

Industries We Serve

Diamond Band Knife Co. is a trusted partner across diverse industries, providing custom CNC blades that meet various cutting demands.

- Furniture Manufacturing: Shape foam and upholstery materials for chairs, sofas, and more.

- Mattress Production: Achieve consistent cuts in various foam densities for comfortable sleep solutions.

- Packaging: Cut cardboard, Honeycomb, foam, and other packaging materials for streamlined production.

- Insulation: Create precise cuts in insulation materials for sound and energy-efficient buildings.

- Automotive: Trim interior components with accuracy for a seamless finish.

No matter your industry, Diamond Band Knife Co. delivers cutting solutions that improve the productivity of your business.

Factors to Consider When Choosing Custom CNC Blades

Alright, so you’re sold on custom CNC blades. But how do you choose the right ones for your application? Here are a few factors to consider.

Material Compatibility

You need to think about material compatibility. Different materials require different blade materials, so you need to choose the right one for the job. We offer various options each suited for specific cutting tasks.

Blade Geometry

The blade’s shape, thickness, and edge profile affect its cutting performance. We tailor these aspects to your needs, offering straight, curved, or wavy geometries.

Tooth Configuration

The size, shape, and spacing of the teeth affect the cut. We offer various tooth configurations to suit different materials, from soft to hard.

Mounting Requirements

Finally, you need to think about mounting requirements. Your custom CNC blade needs to fit seamlessly into your CNC machine, so you need to make sure the length, width, and thickness are compatible.

Extend the Life of Your CNC Blades

Proper care ensures optimal performance and longevity for your Diamond Band Knife Co. blades.

Daily Cleaning

After each use, remove debris from the blade with a soft brush or cloth. For stubborn residue, use a mild cleaning solution designed for cutting tools.

Regular Inspection

Regularly check for chips, cracks, or dullness. Address any issues promptly to maintain cutting efficiency.

Professional Sharpening

Professional sharpening is essential for optimal performance. Contact our team for recommendations on sharpening frequency and services.

Proper Storage

Store your blades in a clean, dry environment away from moisture and extreme temperatures. Protect the cutting edge with a blade guard or sheath.

Get Started with Your Custom Blades Today

Ready to experience the Diamond Band Knife Co. difference? We’ll help you find the perfect blade for your project.

Share your cutting needs with our experts. We’ll discuss your materials, machine, and desired results to determine the ideal blade specifications. Once we understand your requirements, we’ll provide a detailed quote outlining the cost and timeline for your custom blades.

We value your time. We’ll work efficiently to manufacture your blades and ship them to you promptly.

Discover how our custom CNC Contour Cutting Blades can elevate your cutting operations. Let’s create a custom CNC Contour Cutting Blade that works for you.

Diamond CNC blades are meticulously crafted for use with CNC machines, available in two primary configurations for the Reciprocating/Oscillating machine, which seamlessly accommodates non-welded CNC blades, and the Continuous Bandknife Cutting machine.

These specialized CNC blades are designed for cutting both flexible and rigid foam into customized shapes and components used in upholstered furniture, mattresses, and various industries such as packaging and insulation.

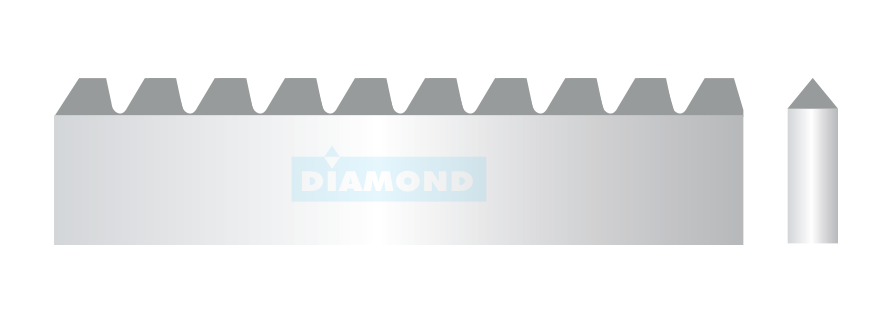

Reciprocating CNC

V Tooth Pointed

Available in: 14, 18 & 24 TPI

The V Toothed CNC Contour Cutting Machine Blades are essential for precision cutting tasks requiring tight tolerances or when dealing with high-density foam materials. Suitable for Reciprocating/Oscillating and Endless Bandknife CNC Contour Cutting Machines.

Width (mm) | Thickness (mm) |

|---|---|

3.00 | 0.60 |

3.60 | 0.60 |

4.50 | 0.60 |

CNC Contour Cutting Bandknife Machine Blades

Knife Edge / DBSE

The Double Bevel Single Edge blade stands as the most ubiquitous cutting edge, serving various cutting, slicing, and peeling tasks. It finds application across vertical, horizontal, carousel, peeling, slicing, and CNC machines.

V Tooth Pointed

Available in: 14, 18 & 24 TPI

The V Toothed CNC Contour Cutting Machine Blades are essential for precision cutting tasks requiring tight tolerances or when dealing with high-density foam materials. Suitable for Reciprocating/Oscillating and Endless Bandknife CNC Contour Cutting Machines.

Flat Tooth

Available in: 10, 12, 14, 18 & 24 TPI

Flat Tooth CNC Contour Cutting Machine Blades offer versatility and excel in processing a wide range of materials. The Flat Tooth profile is widely recognized as the most common choice for converting materials on CNC Contour Cutting Machines. These blades are tailor-made for Endless Bandknife CNC Contour Cutting Machines, ensuring optimal performance.

Angle & Flat Notch

Available in: 10, 12, 14, 18 & 24 TPI

The Angle Flat Notch CNC Contour Cutting Machine Blade showcases a distinct design that harnesses the benefits of the Knife Edge, the Flat Tooth, and the C Tooth, enabling it to efficiently cut a diverse array of products while ensuring durability. This innovative construction is unique to us, as we are the pioneers in offering this profile. We anticipate that others will follow our lead in adopting and providing this exceptional profile.

Width (mm) | Thickness (mm) |

|---|---|

3.00 | 0.45, 0.60 |

3.60 | 0.60 |

3.80 | 0.70 |

4.00 | 0.60, 0.70, 0.80 |

4.50 | 0.60, 0.70, 0.80 |

5.00 | 0.60, 0.70, 0.80 |