Foam

Cutting

Custom Band Knife Blades: Precision Foam Cutting Blades for Your Business

Since 1996, we’ve been the trusted name in precision foam cutting, crafting durable band knife blades that consistently exceed expectations. We know that standard blades don’t always cut it. That’s why we offer custom band knife blades to meet the needs of your industry and materials. Whether you’re working with foam, rubber, fabric, or food, our custom blades will make cutting easier. Browse our selection and experience the Diamond Band Knife Co. difference.

What Are Custom Band Knife Blades?

Custom band knife blades are meant for specific applications. Unlike standard blades with fixed dimensions and tooth configurations, you can design custom blades to your exact specifications. This ensures optimal cutting performance, whether you need a specific blade length, thickness, or width for your machinery or a unique tooth pattern for a particular material.

Benefits of Custom Band Knife Blades

When you choose custom band knife blades, you’ll experience increased efficiency, reduced waste, and improved product quality. The custom design ensures the blade interacts perfectly with your foam material, leading to cleaner cuts and less material waste. Additionally, you can optimize custom blades for cutting speeds and enhanced productivity with precision cuts.

Types of Custom Band Knife Blades at Diamond Band Knife Co.

Diamond Band Knife Co. offers a range of custom blade types to suit diverse cutting needs:

- Straight Blades: Ideal for creating clean, linear cuts in various fibrous or cellular products.

- Scalloped Blades: Use these for trimming or cutting soft materials like foam or rubber with precision.

- Skip Tooth Blades: Choose these blades for efficiently cutting through thick or tough materials such as leather or dense foam.

We can further customize each blade type with varying tooth configurations and blade materials to meet the demands of your application.

Foam Cutting Solutions

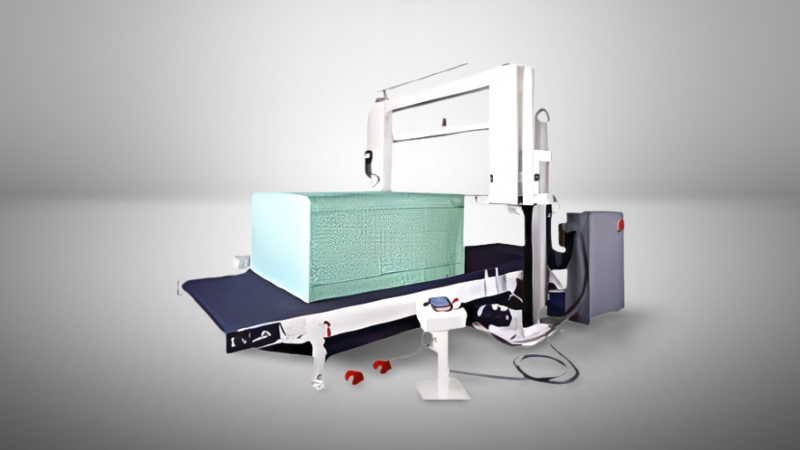

Vertical Foam Slicing

Key to efficient foam processing, custom-configured band knife blades for Vertical Slicing Equipment excel in clean cuts for foam blocks. Their precision is especially beneficial for Flexible Polyurethane Foam and Rebonded Foam, enhancing material use.

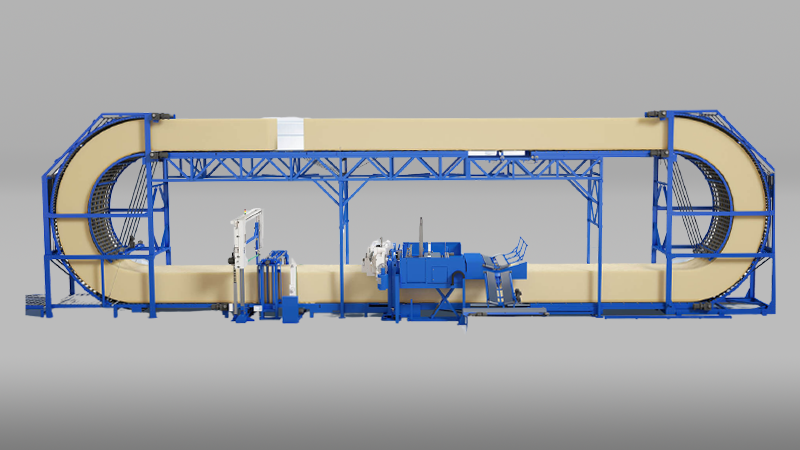

Horizontal and Circular Slicing Equipment

Our adaptable band knife blades, suitable for both Horizontal and Circular slicing systems, are engineered to manage various thicknesses effortlessly. They are a prime choice for mass production, compatible with numerous machinery manufacturers including Sunkist, Hyma, Fecken, Kirfel, Baeumer, Esun, among others.

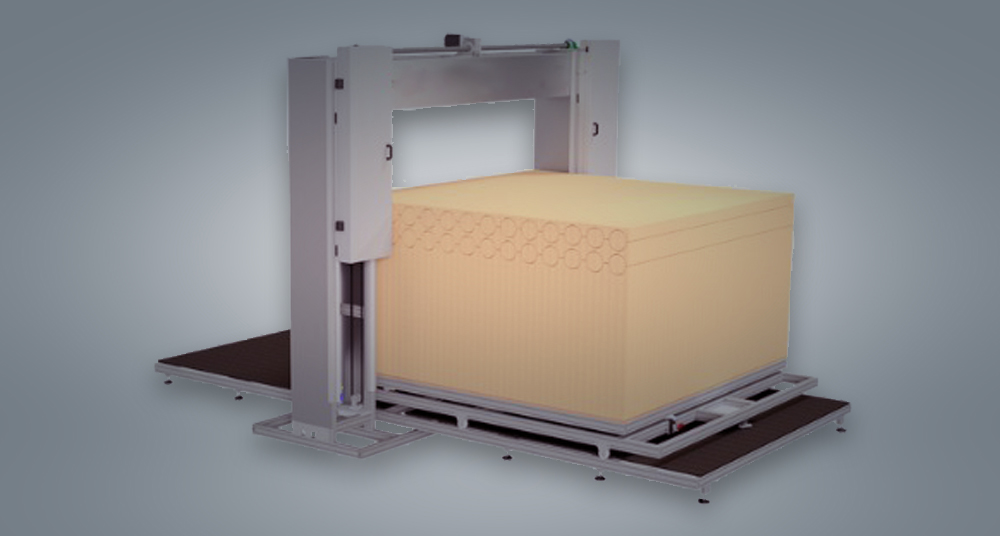

Foam Peeling and Extended Block Slicing

These blades are uniquely developed for peeling devices and extended block slicers, offering unparalleled performance in handling PU foam and equivalent soft materials. They are instrumental in generating premium sheets used in the automotive, packaging, and bedding industries.

CNC Profile Shaping Equipment

Our premium Diamond CNC blades are tailored for both Reciprocating Oscillating and Continuous Bandknife cutting systems, capable of intricately shaping flexible and rebonded foam. These blades are vital for crafting products for the upholstered furnishing, bedding, packaging, and insulation sectors.

Looper Machinery

Our specialized band knife blades for peeling splitting equipment are ideal for transforming long blocks into slender sheet rolls. We provide custom sizes to fit a variety of splitting machinery.

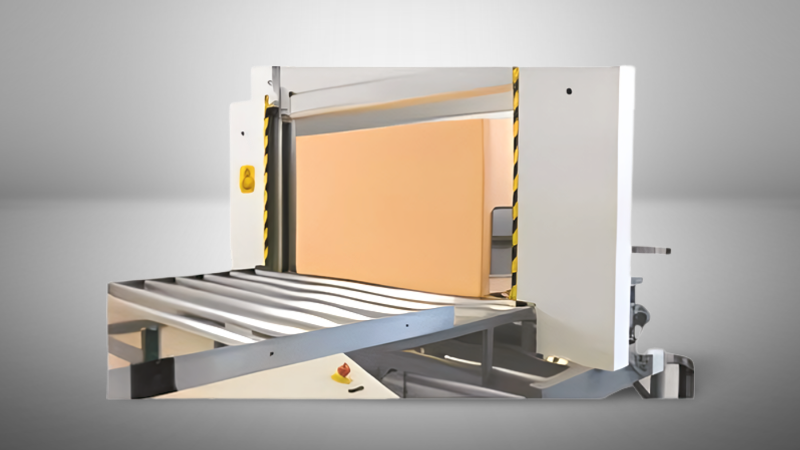

Block Slicing-Guillotine and Vertical Applications

Our trusted block slicer blades are designed to reduce downtime and boost efficiency in foam creation processes. Endorsed by Laaderberg as an OEM supplier, our blades stand as a testament to our dedication to unparalleled quality.

Abrasive Wire for Profile Slicing

Enhance your manual or automated abrasive wire systems with our Diamond Abrasive Cutting Wires. Engineered for an extensive array of PU foam densities and rebonded foam, these wires guarantee durability and a flawless surface finish.

Build Your Perfect Blade

To ensure optimal performance, you can customize your band knife blade to meet your needs. We offer various options to tailor the blade perfectly to your application.

Dimensions

You can specify the blade’s length, width, and thickness to match your existing machinery and desired cutting parameters.

Tooth Configuration

Choose from tooth configurations like a regular tooth, skip tooth, or scalloped patterns. Each pattern suits different materials and cutting styles, ensuring you have the right blade for the job.

Blade Material

Select the blade material that best suits your needs. Options include carbon steel, stainless steel, and tool steel, each with varying levels of hardness, durability, and corrosion resistance.

Partner With Diamond Band Knife Co. for Precision Foam Cutting

Choose the ideal custom knife blade that matches your requirements. Diamond Band Knife Co. is here to guide you through the selection process. Contact us today to explore our range of custom band knife blades and find the perfect solution for your application.

1. Custom Made Band Knife Blades For Vertical Foam Cutting

Bandknife blades for the Vertical Cutting Machines are essential for precise trimming and splitting of Flexible PU Foam and Rebonded Foam blocks, maximising material utilisation in foam conversion.

2. Custom Made Band Knife Blade For Horizontal/Circular Cutting Machine

Bandknife blades are versatile tools for cutting a wide range of materials in Horizontal and Circular machines. They handle different thicknesses with precision, ideal for large-scale production, fit various foam cutting machines like Sunkist, Hyma, Fecken Kirfel, Baeumer, Esun, and others, ensuring uninterrupted workflow and enhanced efficiency.

3. Custom Made Band Knife Blade For Peeling Machine / Long Block Cutter

Bandknife blades designed for peeling machines are ideal for processing PU foam and similar soft materials, including peeling heavy blocks to produce long and thin sheets. These specialized blades are tailored to meet the rigorous demands of industries such as automotive and mattress manufacturing. With exceptional precision and efficiency, these band knife blades consistently deliver smooth and flawless peeling, ensuring consistent sheet thickness. They support the seamless production of high-quality sheets for various industrial applications.

4. Custom Made CNC Contour Cutting Bandknife Machine Blades

Diamond CNC blades are meticulously crafted for CNC machines. These machines come in two primary configurations the Reciprocating/ Oscillating machine, which seamlessly accommodates non-welded CNC blades, and the Continuous Bandknife Cutting machine, precisely engineered for welded CNC blades. These specialized CNC blades serve the purpose of cutting both flexible and rebonded foam into customized shapes and components, upholstered furniture, and mattresses, as well as in the packaging and insulation industries.

5. Custom Made Band Knife Blade For Cnc Contour Machine - Oscillating Type

Embark on a journey of precision and craftsmanship with our custom band knife blades, designed for CNC contour machines, especially the oscillating type. These blades blend innovation and technology, offering unmatched performance for intricate cutting tasks. Whether sculpting designs or navigating complex contours, our blades redefine precision and efficiency. The oscillating motion enhances versatility, adapting seamlessly to various materials and patterns. Elevate your CNC cutting with blades that exceed demands. Choose our blades for reliability, precision, and excellence in every cut. Opt for a new standard of craftsmanship with our unparalleled cutting experience.

6. Custom Made Band Knife Blade for Looper

7. Custom Made Band Knife Blade For Block Cutter-Guillotine & Vertical

8. Custom Made Abrasive Wire For Contour Cutting

Experience cutting-edge innovation with Diamond Abrasive Cutting Wires, designed to perfectly complement your abrasive wire machines whether it be manual or Automatic. Suitable for cutting a wide range of PU foam densities and rebonded foam, Diamond Abrasive Cutting Wires guarantee endurance and a smooth finish.