Tissue Roll and Napkin Conversions

Bandknife Blades

Through the use of the appropriate steel and meticulous production processes, our tissue paper and napkin conversion blades are designed to work consistently without losing efficiency, even when other tools may have reached their limits. The careful selection of materials and manufacturing techniques ensures that these tissue paper and napkin conversion blades remain effective for extended periods.

Knife Edge / DBSE

The Single Bevel Single Edge blade is specifically designed for peeling and slicing tasks. It is frequently employed on horizontal cutting machines.

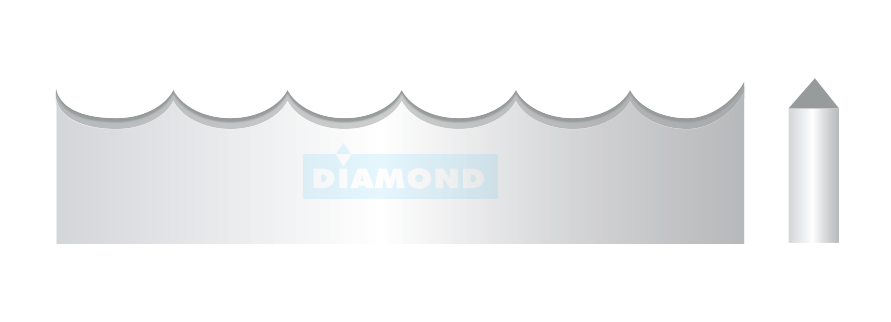

Concave - DBSE

Available in: 2 & 4 TPI

The Concave Double Bevel Single Edge, also known as the Scalloped Edge, undergoes profile grinding to create a hybrid version combining attributes of the Knife Edge and the Serrated profile, resulting in superior cutting performance. This profile, widely recognized as the most popular choice, finds applications across various industries. It is employed on both horizontal and vertical cutting machines.

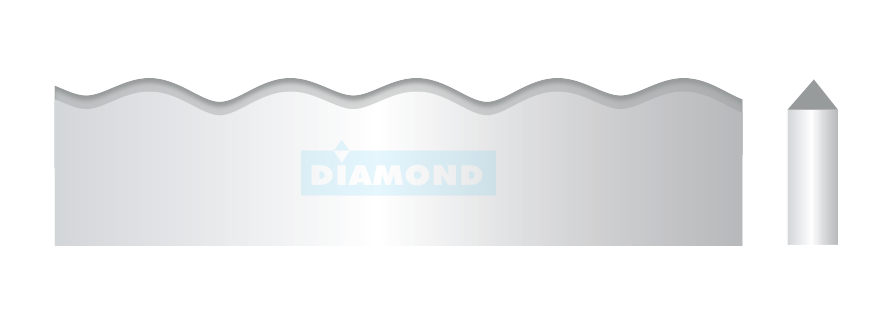

Convex – DBSE

The Convex/Wavy-DBSE is a gentler and less aggressive alternative to the Concave/Scallop profile. It retains the advantages of a knife edge while allowing interrupted cutting without material tearing, thus minimizing dust generation. This profile is suitable for use with both horizontal and vertical cutting machines.

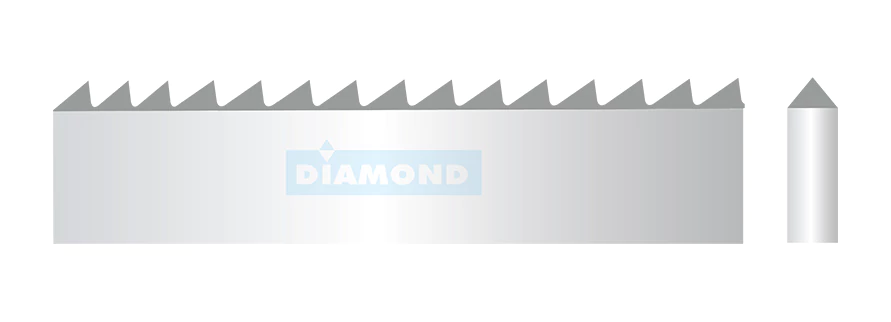

V tooth Serrated DBSE / Diamond Pointed Tooth

Available in: 6, 8, 10, 14 & 18 TPI

The V toothed pointed is a popular profile. This profile is aggressive as compared to the knife edge blade. Generates some dust. Good for cutting hard foams and helps in avoiding the sharpening mechanism on the cutting machine. Used on vertical, horizontal, carousel, and CNC machines.

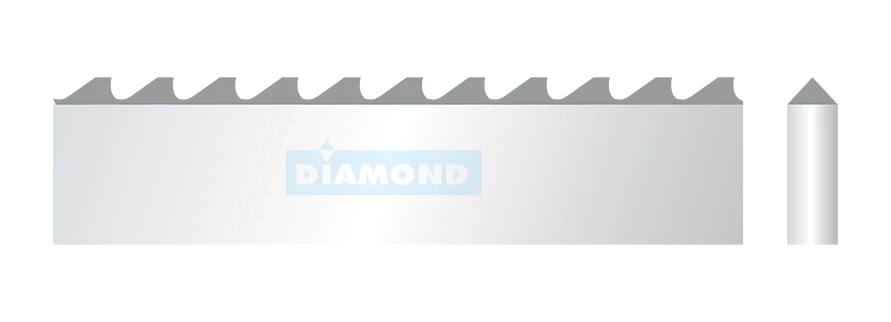

Angle Tooth DBSE / C type

Available in: 2, 4, 6, 8, 10 & 14 TPI

The Angle Toothed Double Bevel Single Edge is far more aggressive in its cutting action.

Notch Tooth DBSE

The Notch Tooth DBSE is specifically engineered for foam cutting applications, offering exceptional precision and control. Its unique notch tooth design allows for clean and accurate cuts through various densities of foam materials, including polyurethane foam, memory foam, and foam rubber.

Width in mm | Thickness in mm |

|---|---|

20 | 0.45 / 0.50 / 0.60 /0.70 |

25 | 0.45 / 0.50 / 0.60 / 0.70 |

30 | 0.45 / 0.50 / 0.60 / 0.70 |

32 | 0.50 / 0.60 |

35 | 0.50 / 0.60 |

40 | 0.50 / 0.60 / 0.70 |

50 | 0.50 / 0.60 / 0.70 / 0.80 / 1.00 |

60 | 0.60 / 0.70 / 0.80 / 1.00 |

80 | 0.60 / 0.80 |

90 | 1.0 / 1.20 |

100 | 1.00 / 1.20 |

Width in Inches | Thickness in Inches |

|---|---|

0.787 | 0.017 / 0.019 / 0.023 / 0.027 |

0.984 | 0.017 / 0.019 / 0.023 / 0.027 |

1.181 | 0.017 / 0.019 / 0.023 / 0.027 |

1.259 | 0.019 / 0.023 |

1.377 | 0.019 / 0.023 |

1.574 | 0.019 / 0.023 / 0.027 |

1.968 | 0.019 / 0.023 / 0.027 / 0.031 / 0.039 |

2.362 | 0.023 / 0.027 / 0.031 / 0.039 |

3.149 | 0.023 / 0.031 |

3.543 | 0.039 / 0.047 |

3.937 | 0.039 / 0.047 |