Vegetable Harvesting & Slicing

Bandknife Blades

Leafy Vegetables Harvesting

Not all leafy vegetables are alike; each type requires a specific solution due to variations in shape, texture, and other characteristics. Tailored harvesting methods are essential to prevent damage and preserve quality. Diamond has developed a diverse range of bandsaw blades designed to adapt to different harvesting situations, ensuring precise, delicate, and safe operations. Diamond offers a comprehensive selection of bandsaw blades to meet harvesting requirements. Diamond’s advanced technology optimizes harvesting times while reducing costs. These bandsaw blade solutions are ideal for harvesting a variety of vegetables and herbs including Mint, Basil, Spinach, Parsley, Coriander, Salad, Chard, and other varieties. Choose your desired product and discover which Diamond bandsaw blade best suits your needs.

Knife Edge / DBSE

The Double Bevel Single Edge blade stands as the most ubiquitous cutting edge, serving various cutting, slicing, and peeling tasks. It finds application across vertical, horizontal, carousel, peeling, slicing, and CNC machines.

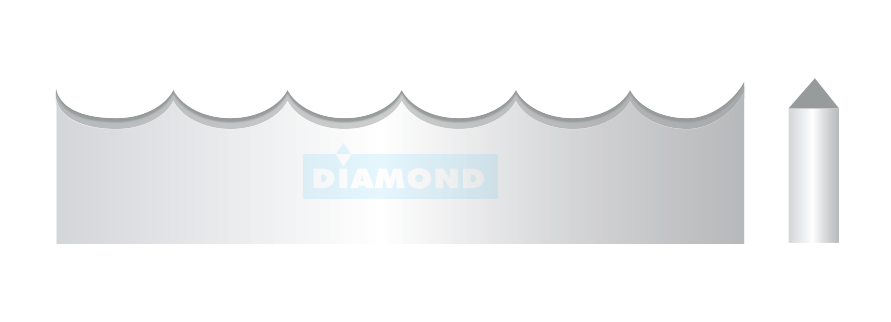

Concave - DBSE

Available in: 2 & 4 TPI

The Concave Double Bevel Single Edge, also known as the Scalloped Edge, undergoes profile grinding to create a hybrid version combining attributes of the Knife Edge and the Serrated profile, resulting in superior cutting performance. This profile, widely recognized as the most popular choice, finds applications across various industries. It is employed on both horizontal and vertical cutting machines.

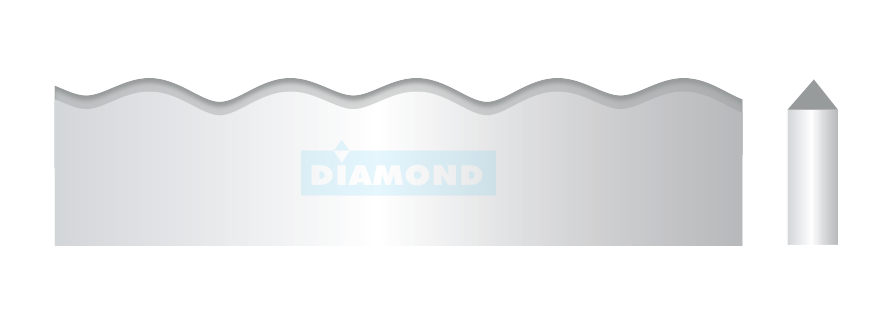

Convex – DBSE

The Convex/Wavy-DBSE is a gentler and less aggressive alternative to the Concave/Scallop profile. It retains the advantages of a knife edge while allowing interrupted cutting without material tearing, thus minimizing dust generation. This profile is suitable for use with both horizontal and vertical cutting machines.

V tooth Serrated DBSE / Diamond Pointed Tooth

Available in: 6, 8, 10, 14 & 18 TPI

The V toothed pointed is a popular profile. This profile is aggressive as compared to the knife edge blade. Generates some dust. Good for cutting hard foams and helps in avoiding the sharpening mechanism on the cutting machine. Used on vertical, horizontal, carousel, and CNC machines.

Width in mm | Thickness in mm |

|---|---|

6 | 0.5 |

10 | 0.40 / 0.45 / 0.50 |

11 | 0.4 |

13 | 0.50 / 0.65 / 0.80 |

15 | 0.45 / 0.50 / 0.56 / 0.65 |

19 | 0.45 / 0.50 / 0.65 / 0.80 / 0.90 |

25 | 0.50 / 0.65 / 0.80 / 0.90 |

30 | 0.45 / 0.50 / 0.65 / 0.80 |

38 | 0.50 / 0.60 / 0.65 / 0.80 / 0.90 |

Width in Inches | Thickness in Inches |

|---|---|

0.236 | 0.019 |

0.393 | 0.015 / 0.017 / 0.017 |

0.433 | 0.015 |

0.511 | 0.019 / 0.025 / 0.031 |

0.590 | 0.017 / 0.019 / 0.022 / 0.025 |

0.748 | 0.017 / 0.019 / 0.025 / 0.031 / 0.035 |

0.984 | 0.019 / 0.025 / 0.031 / 0.035 |

1.181 | 0.017 / 0.019 / 0.025 / 0.031 |

1.496 | 0.019 / 0.023 / 0.025 / 0.031 / 0.035 |